Industry Spotlight: Reducing Carbon Intensity for a Plastic Polymers Plant

- 19.8 MW of proposed electric capacity, with six 3.3 MW hydrogen-ready generators sized according to plant expansion plans

- Load following and island mode capabilities

- Waste heat used to produce industrial steam

- Carbon footprint reduced by 34%, or 46,000 tons per year, with a long-term carbon reduction timeline for 80% reduction

- Eligible for the maximum 50% ITC tax credit, including a 30% microgrid ITC, 10% for the plant’s location in a brownfield area, and an additional 10% hydrogen bonus

Proforma Details

A plastic polymers industrial company located in the Gulf Coast initially came to Unison Energy looking for a solution to reduce its carbon emissions. Industrial sites are difficult to decarbonize, and this site was no exception, as its petrochemical processes required a large amount of heat and electricity. What’s more, the site was located in a high-carbon-emitting area, where utility power had a higher carbon intensity than the national average.

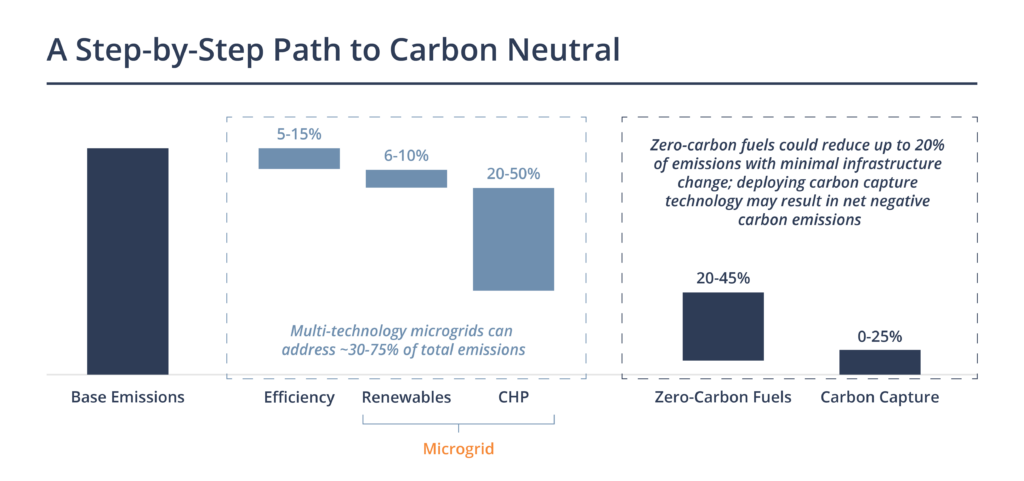

With our initial plan, a cogeneration-based microgrid would cut the site’s carbon intensity by 34% in real, quantifiable emissions. Rather than relying on offsets or VPAs, our project offered an on-site solution for making this specific industrial process less carbon-intensive.

However, as a European-owned company, the polymers plant had an aspirational carbon reduction target — and we had a plan to help them meet that goal. Thanks to nearby infrastructure, the site had a unique opportunity to cut emissions by as much as 80% over time. This was possible thanks to the site’s location near a hydrogen pipeline, as well as a CO2 pipeline and rail line, which allowed for incorporating low carbon fuel in the form of hydrogen or a hydrogen blend, as well as post-combustion carbon capture.

Unison Energy created a multi-step plan for reducing the plant’s emissions over the next 5-7 years, using hydrogen fuel and carbon capture, to achieve their corporate 2030 carbon reduction goals.

- Hydrogen: Because our CHP engines are hydrogen-ready, we could integrate hydrogen fuel from the adjacent pipeline to provide carbon-free electricity and steam. Or, we could integrate hydrogen fuel to reduce the carbon intensity of the natural gas used in the CHP systems.

- Carbon Capture: Including carbon capture as a service, we would modularly add carbon capture alongside our CHP generators. We would then sell the captured CO2 for use locally at a nearby refining plant. Alternatively, with both a pipeline and rail line nearby, we could readily transport the captured CO2 to be sequestered elsewhere.

Due to their Gulf Coast location, resiliency was also a concern for this potential client. Their industrial process is continuous, running 24/7, and extremely expensive to stop and restart — making resiliency a critical business and safety need. Our CHP microgrid offered load-following, island mode capabilities to keep the site operational when the grid went down, and we could size the installation to meet the current and future needs of the facility.

Thanks to our Energy as a Service model, all of this was possible while ensuring cost savings for the client. With our proforma, this site’s proposed cost savings started at $450k in the first year and reached $25.7 million in savings over the 20-year term period. The site also had the time-limited potential to receive up to a 50% ITC tax credit thanks to the Inflation Reduction Act. This included the 30% base credit for a low-carbon energy project, as well as the 10% bonus credit for brownfield sites, and the 10% hydrogen or carbon capture bonus. By acting quickly, the site would be able to take advantage of these tax savings while starting on a realistic path toward its sustainability targets.

Learn how a Unison Energy solution could help you reach your energy goals. Get in touch for an initial site assessment.

"Thanks to nearby infrastructure, the site had a unique opportunity to cut emissions by as much as 80%."

Featured Insights

FedEx Lehigh Valley Distribution Hub: On-Site Power Delivering Resilience

Centersquare BOS1-A Data Center: A Premier Data Center Offering Scale, Security, and Enhanced Reliability with Unison’s Microgrid Technology

Industry Spotlight: Meeting Sustainability and Resiliency Goals for Dairy Producers