Energy as a Service – Outsource Microgrid Risks and Maximize Benefits

Third-party ownership and operations allows facilities to implement on-site power generation while avoiding the financial and operational risks associated with owning and operating a complex system.

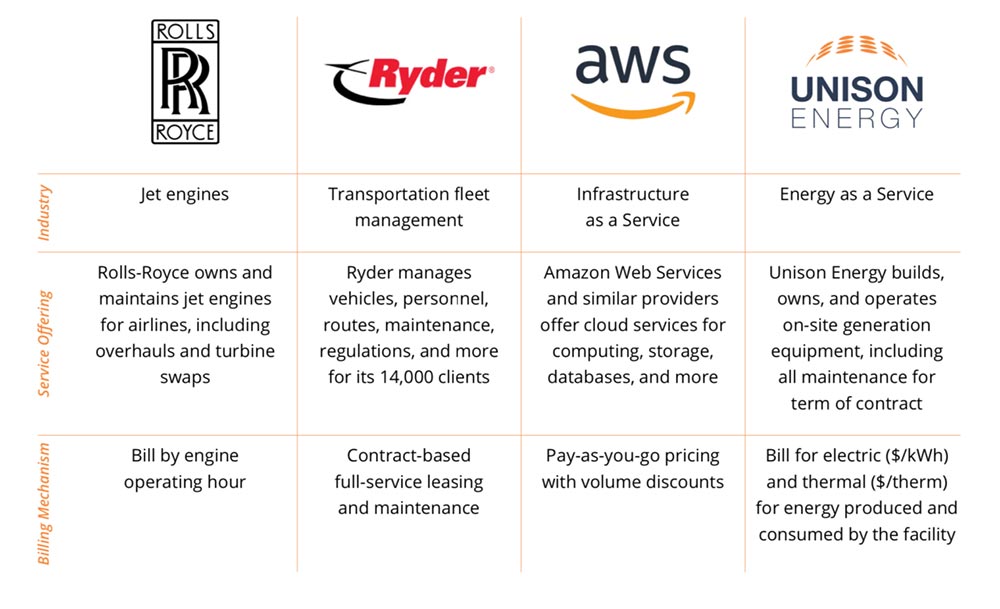

For decades, industries have been shifting the operational and financial risks of complex and capital-intensive systems to outsourcing firms that have the expertise and capital to manage these risks. These firms leverage a portfolio effect to balance financial risk on any single site across a fleet of assets. Jet engines, truck fleets, and IT resources have all been outsourced.

Energy as a Service (EaaS) follows this trend. Contracting with a third party to build, own, and operate microgrids and on-site generation replaces the traditional model of purchasing a system and signing a maintenance contract — a model that has left too many facilities exposed to cost overruns, underperforming assets, and unexpected maintenance costs.

Allocate Risk to the Operators

Outsourcing through the EaaS model lets facilities offload and avoid the financial and operational risks that might otherwise undercut the potential benefits of a microgrid.

Purchasing an on-site cogeneration system and signing a maintenance contract leaves the financial and operational risks in the facility’s hands. It requires the facility to put down money upfront, and when costly problems arise, it’s the facility’s balance sheet that takes the financial hit. Meanwhile, relying on a “break-fix” model for maintenance assumes the facility is extremely diligent with proactive maintenance, monitoring, and testing. When other facility operations tasks take precedence, service contractors or parts aren’t available, or costs exceed available budgets, maintenance is delayed or problems aren’t detected until too late. Performance issues inevitably follow, reducing the cost-saving benefits of the microgrid.

Energy as a Service (EaaS) providers use an Energy Services Agreement (ESA) where the provider pays for engineering, permitting, equipment, construction, and all of the maintenance over the term of the contract. In return, they bill for energy produced and consumed by the facility. Since there is no upfront cost with an ESA, the energy system stays off the facility’s balance sheet. Any cost overruns, early maintenance requirements, or parts replacements are the responsibility of the provider. An ESA puts financial risk on the provider’s plate.

Focus on Your Business and Entrust Microgrid Operations to the Experts

Facilities should not let on-site energy generation draw focus away from their core competencies. With EaaS outsourcing, a facility can rely on experts who already know the ins and outs of microgrid management.

With a third-party maintenance contract, an on-site facility employee will still have to be responsible for the day-to-day operations of the system. When a third-party technician visits the site for maintenance, they come out infrequently and may not be the same technician. The technician likely will not be familiar with the day-to-day operations of this particular system and how it ties in with the overall facility. Important details can be overlooked. The result could be an underperforming, costly piece of equipment that may experience higher downtime.

With EaaS, the facility benefits from working with experts who design, construct, and operate a system that works for the facility’s goals and delivers high performance. Years of operating systems feeds back into the design of new systems. EaaS providers have the experience to thoroughly assess a facility’s energy usage patterns and requirements to design the “right” system for the site. A qualified provider has installed — and operated — dozens of systems, understands the intricate utility interconnect and permitting process, and is familiar with available utility rebates and incentives that can subsidize the cost structure. These experts work closely with the facility to ensure the CHP system will meet its needs for a decade or more.

Once the system is up and running, operations personnel are assigned to the site and become deeply familiar with the facility and the system. As the day-to-day operators of the site, they are physically present — they will recognize when something “seems different” from usual operations and take the time to fix it before it becomes a problem.

These operators have in-depth site knowledge but also have data from operating a fleet of similar systems. The provider can use remote and in-person data collection to diagnose issues, optimize operations, and build a powerful database of information. While access to remote data is not unique to an EaaS provider, what is unique is that they can combine this data with personal knowledge of the site from day-to-day operations and the designbuild process.

The EaaS provider is also more likely to invest in developing operating capabilities by training personnel, investing in technology, forming industry relationships, and finding new ways to ensure and enhance performance, as this benefits both parties’ bottom lines.

Align Your Incentives With the Operator

An ESA ensures both parties sit on the same side of the table and focus on uptime goals.

System downtime can quickly cut into a facility’s financial benefits and can even put its operations at risk if it occurs at an inopportune time, like during a grid outage. Yet typical maintenance contracts aren’t focused on proactively avoiding downtime, but rather on reactively fixing problems that have already occurred.

A better outsourcing model is one where both parties are financially interested in ensuring high levels of uptime. With an ESA contract, the provider only makes money when the facility’s system is working as intended. Incentives are aligned because if the system goes down and is no longer providing the customer value, it isn’t generating revenue for the provider either.

That’s why EaaS providers take deliberate steps to ensure high uptime. The operations team takes ownership of the specific site and checks on it daily, whether through in-person examination or remote data checks. They perform proactive maintenance, with spare parts kept on hand, to reduce the risk of outages and avoid downtime spent waiting for required parts. The provider also sets uptime standards across their fleet as a whole and has the experience to reach and raise that standard over time.

Benefit From an Increasingly Common Business Model

Many businesses today retain a focus on their primary objectives by outsourcing capabilities that don’t fall under their area of expertise. As one of our hospital clients relayed at the beginning of COVID-19, “You keep the lights on, we’ll keep people healthy. It’s a great partnership.”

One early example of equipment outsourcing was Rolls-Royce, which began offering a “Power by the Hour” model in the 1960s. Instead of purchasing and maintaining jet engines, airlines would pay Rolls-Royce a fee for every hour the jet engine operated and Rolls-Royce would pay for the equipment and all of the maintenance. Today, General Electric, Pratt & Whitney, and Rolls-Royce all have performance-based contracts for the parts they supply to commercial airlines.

Similarly, fleet management is a commonly outsourced capability, as most companies do not have the bandwidth to take it on. Fleet management means coordinating vehicles, personnel, routes, regulations, and more, and most companies prefer to pursue a turnkey solution. For instance, Ryder System, Inc., manages some 180,000 vehicles across 14,000 companies, offering a more cost-effective and fully optimized solution for their customers. Ryder System, Inc. provides rich data and best practices that customers can’t achieve on their own.

Outsourcing capabilities are also common in IT, where the software as a service (SaaS) or data storage as a service (STaaS) model allows companies to enjoy the benefits of the cloud, including scalability, flexibility, and security, all handled by the provider. In many cases, companies pay just for the cloud space they actually use, further showing how outsourcing models can be a smart financial move.

Unison Energy’s EaaS model aligns with these other well-known business practices. Unison offers 15-20 year ESAs where the client pays just for energy usage with no capital expenditure required. Facilities can reduce their financial and operational risk because Unison’s team of experts designs, builds, owns, and operates the system. Unison develops deep familiarity with each facility’s system and provides hands-on support during power outages. Incentives are aligned to achieve higher uptime at a lower operating cost because Unison only generates revenue when its systems are operational.

Examples of Equipment Outsourcing Models

Enjoy the Benefits of CHP Without the Risks

Cogeneration systems are attractive for a range of sites, from industrial facilities and hospitals to data centers, distribution centers, and large hotels that are eager to benefit from energy cost-savings, resiliency, and carbon reductions. In order to allocate risk and achieve better outcomes, these facilities should establish a partnership with an experienced EaaS provider who handles the risk and responsibility, leaving the facility free to enjoy the benefits without the risk.

The Unison Energy service operations model is designed to ensure your facility experiences industry-leading uptime. Click here to contact a Unison Energy sales representative

Energy insights, delivered

Subscribe for more content.