How Cogeneration Enhances Your Sustainability Program

Cogeneration-based microgrids can reduce carbon footprint by 20-60% for hospitals, industrial facilities, hotels, and other large facilities.

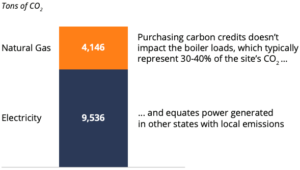

Many corporations, healthcare facilities, and universities are making ambitious commitments to cut carbon emissions. Some, in a bid to offset their electrical usage, are purchasing carbon credits from wind or solar farms in other states — a good first step but one that does not actually reduce carbon emissions from their on-site electricity and natural gas usage.

One solution: Installing cogeneration or combined heat and power (CHP) systems that cut carbon emissions from on-site energy usage by 20-60% (depending on location and thermal load). Instead of paying for credits, businesses can install CHP systems using a zero-investment energy services agreement (ESA). For instance, Peninsula Regional Medical Center installed a CHP system in 2018. In the first year, Peninsula not only cut costs and maintained energy resiliency, but reduced its carbon footprint by an impressive 58%.

Calculating Facility Carbon Emissions

Total facility carbon emissions include both electricity and fuel consumption. When calculating emissions, facilities must take into account their electricity usage (including the carbon intensity of their electricity source) and the natural gas or other fuels used for boilers, chillers, and industrial processes. Many companies today only focus on their electricity usage and its carbon intensity. However, natural gas consumption typically comprises up to 30% of total emissions for hospitals, universities, hotels, and manufacturing facilities.

- Electricity: Electricity emissions are calculated by the mix of generation on the grid. On average, the U.S. generates 947 lbs of CO2/MWh.

- Natural Gas: Each MMBTU of natural gas used by the facility produces 117 lbs of CO2.

When in island mode, microgrids provide on-site power generation that supports facility operations indefinitely, until utility service can be restored.

How CHP Can Reduce Carbon Footprint

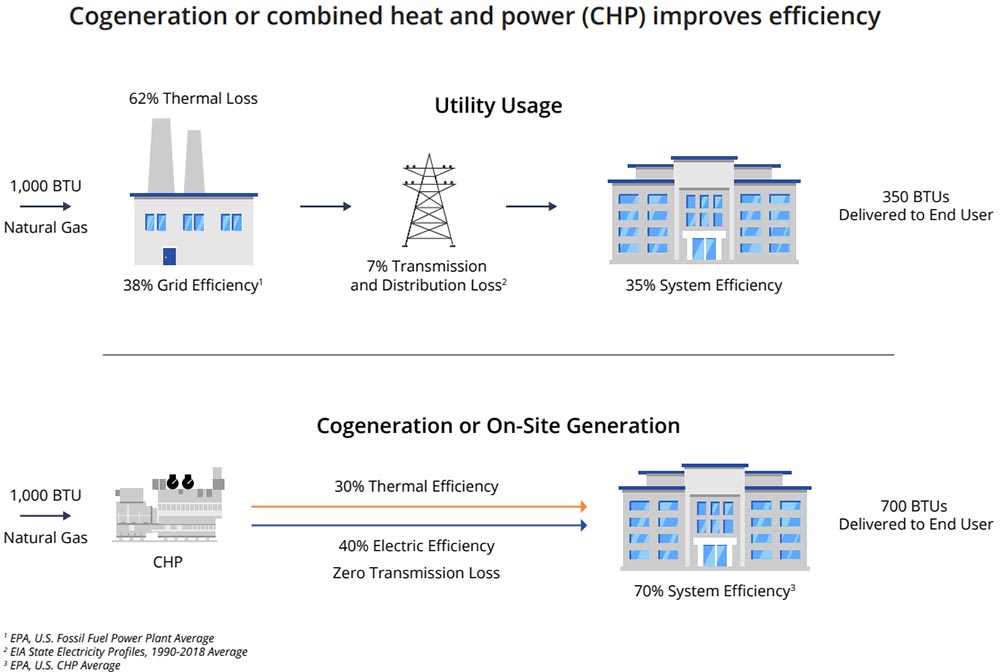

First implemented by Thomas Edison in 1882, CHP efficiency is an old idea that is even more relevant in our age of combating climate change. In effect, a CHP system allows a facility to do more with less. A combined heat and power system is an on-site power generation system that uses a single fuel source, typically natural gas, to simultaneously produce both electricity and thermal energy:

- Turbines or reciprocating engines use natural gas to power a generator which creates electricity.

- Waste heat from the exhaust or jacket water is captured and used to create hot water, steam, or chilled water.

- Hot water or steam is piped into the facility, reducing or eliminating the need for boilers and thus reducing the amount of natural gas used.

- Chilled water from an absorption chiller is used in refrigeration or chilling systems to reduce the amount of electricity required to run the traditional HVAC and refrigeration compressors.

According to the EPA, a typical fossil fuel power plant on the grid is only 38% efficient and loses 62% of fuel input energy as heat. The EPA estimates that by recapturing this heat, cogeneration can achieve annual system efficiencies of 60-80%, with reciprocating engines offering 75-80% efficiency and CHP steam turbines reaching 80% efficiency. The National Resources Defense Council estimates that a CHP system can reduce CO₂ emissions by 4,000 metric tons for each MW of installed capacity. Additionally, a facility with on-site CHP avoids transmission and distribution losses — 7% on average over the last 30 years, according to the EIA — that occur with long-distance energy transfer over the grid.

Assessing the Impact of a CHP System

An important factor in determining a facility’s potential carbon savings with CHP is to identify the power generation sources on the regional grid.

According to the U.S. Energy Information Administration, electricity generation across the U.S. came from the following energy sources in 2019:

- Coal: 24%, with an average CO₂ emissions rate of 2,210 lbs/MWh

- Natural Gas: 38%, with an average CO₂ emissions rate of 920 lbs/MWh

- Nuclear: 20%, zero emissions, clean but not renewable

- Hydro: 7%, zero emissions, renewable

- Non-Hydro Renewables: 11%, zero emissions, renewable

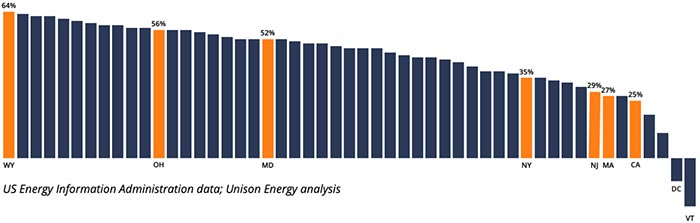

However, emission rates vary by state, depending on the fuel mix used in that state. Facilities can calculate their potential emissions reductions more accurately by considering local generation sources. For instance, the EPA notes that approximately 53% of California’s power comes from clean sources — solar and wind (21%), hydro (14%), nuclear (9%), geothermal (6%), and biomass (3%) — while in contrast, over 86% of Wyoming’s power comes from coal. Therefore, a facility in California using the same amount of electricity as one in Wyoming has a lower carbon footprint or lower carbon intensity.

Despite these differences across states, a CHP system can still offer significant emission reductions almost anywhere in the country. For example, with the exception of Vermont and Washington, D.C., which rely almost entirely on hydro and nuclear power, a 70% efficient CHP system would reduce carbon emissions by 25-60% in any state in the country.

Example Carbon Savings From a 70% Efficient CHP System, by State (%)

A Unison Energy CHP system can reduce CO₂ by 20-60% in any state in the country

Choosing Cogeneration

Consider the example of Peninsula Regional Medical Center, where Unison Energy installed two 1.5 MW reciprocating engines that provide the hospital with 81% of its electricity. In this 65% efficient CHP system, each engine has heat exchangers in the exhaust stack and embedded in the engine jacket water loop in order to capture all available waste heat and feed a single hot water loop to the facility.

This hot water loop ties into the hospital’s hot water distribution system, allowing the hospital to turn down its boilers to a low-fire setting for most of the year. As a result, the hospital has reduced its carbon footprint by 58%, based on the EPA’s CHP emissions calculator — especially significant given that hospitals are highly energy-intensive facilities.

Even after more than a century of innovation in the power sector, cogeneration remains one of the most energy-efficient solutions available. Over 4,400 facilities in the U.S. currently use CHP systems across a range of industries, including hospitals, groceries, and industrial facilities. For these businesses, cogeneration systems offer not just reliable and cost-effective energy, but a way to meet or exceed the critical emissions reductions laid out in your sustainability goals.

For more information on how CHP can help your organization achieve its sustainability goals, click here to contact Unison Energy.

Energy insights, delivered

Subscribe for more content.

Related Blogs

The Energy Crisis in Healthcare: Mitigating Financial Losses Through Reliable Power Solutions

Deadlines for the Inflation Reduction Act

Canadian Carbon Reduction Incentives: What You Should Know