Designing Microgrids for Multi-Building Campuses

Large campuses are ideal candidates for microgrids. A distributed microgrid can provide critical resiliency, sustainability, and cost-saving benefits even for the most complex sites.

Large campuses can be complicated for installing microgrids. Some campuses are fortunate to have a central utility plant with centralized electric feeds and thermal loops, plus plenty of space right next to the plant. These are easy microgrid installations as there is room for on-site generation equipment and a single place to tie into electrical distribution systems and thermal loops.

However, most campuses are more distributed and may have challenging layouts, as they have added electrical services, boiler rooms, and chiller plants over time while they have built new towers, wings, or outlying buildings.

Nonetheless, even multi-building campuses without a central plant are able to deploy microgrids. Unison Energy has successfully designed, built, and operated microgrids for campus environments with distributed services.

Microgrids or Distributed Generation Can Cover Unique Multi-Building Configurations

Despite the challenging layouts of some campuses, microgrids utilizing combined heat and power (CHP) can generate electricity for the buildings with the largest loads while providing hot water, steam, and chilled water to meet the site’s thermal needs.

Most campuses have unique setups and complex configurations that appear to preclude the possibility of a cogeneration-based microgrid. While some large campuses do have large central plants, they simply do not have the square footage to add a microgrid solution. Some may have electrical feeds with multiple meters but a central plant with campus-wide thermal loops, while others have both multiple electrical feeds and local heating and chilling plants.

Although connecting to a central plant is the most straightforward option in terms of costs and constructability, and especially in terms of thermal integration, other solutions that work with these multi-building configurations can still be cost-effective. Unison Energy approaches the design of a campus microgrid with four steps:

- The first step is to assess the campus loads and priorities for resilience. Typically, a few large, critical buildings make up 80% of the load and most of the critical operations. Distributed microgrid systems can be placed around the campus at individual buildings, where they are sized to match the individual building electric loads and combine with individual utility feeds. Co-located buildings that share a meter can allow the system to connect the loads between buildings, improving the overall resiliency of the microgrid.

- Second, assess the campus’s thermal needs. CHP systems can also provide hot water, steam, and chilled water back into the campus’ thermal systems, which typically have a wider reach across many buildings than the electrical connections. Alternately, the waste heat can be used to meet the needs of a specific building, as hospitals and university campuses frequently have multiple boiler rooms to support the different thermal uses for different buildings.

- The third step is to identify space constraints. Frequently, it is easier to find multiple smaller footprints throughout the campus than a large footprint in a central location, especially in crowded urban campuses. Opportunities may include smaller sections taking up a few parking spots, the room next to a loading dock, or removing decommissioned equipment.

- As an additional benefit, many campuses take the opportunity of installing a microgrid as a great way to update facility infrastructure; the fourth step is to assess these opportunities. Campus buildings are often constructed in a piecemeal fashion over time, and old buildings may be in dire need of updates to their old electrical infrastructure, boilers, chillers, or cooling towers. With an energy services agreement (ESA), where Unison Energy installs, owns, and operates the system, additional infrastructure upgrades can be included in the agreement’s cost-reducing savings, compared with the normal capital budget process where paying for critical infrastructure upgrades may be more difficult.

Case Study: Installing CHP for a Multi-Building Campus

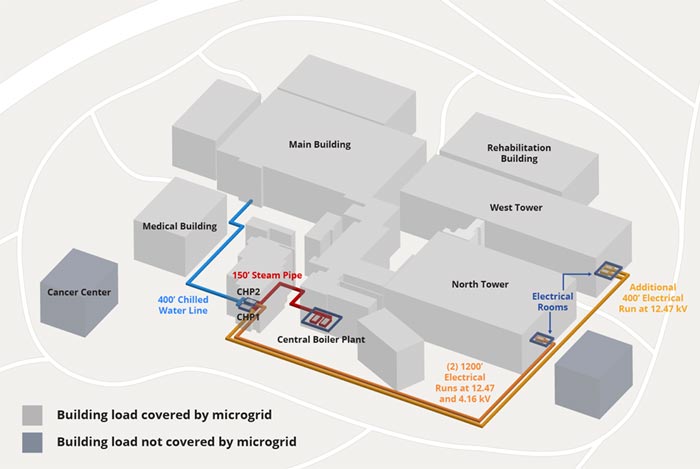

For a hospital campus in California, Unison Energy designed a system to offer 3,012 kW of CHP generation over three electrical meters, while boiler plant upgrades and CHP waste heat doubled the hospital’s capacity for peak steam demand.

One of Unison Energy’s current clients is a large hospital campus in Southern California that was interested in saving money on its high energy costs while improving its operational resiliency and reducing its carbon footprint. The facility also needed to make critical repairs to the central plant infrastructure. The campus had grown substantially over the decades and consisted of 35 buildings spread over 30 acres, posing a challenge for a microgrid installation.

Electrical configuration was the main challenge: the hospital’s 35 buildings were powered by 12 different utility meters of different voltages, spread across the campus, making it impossible to combine the meters for a single on-site generation solution. On the other hand, the hospital’s thermal system was centralized. A central boiler plant fed steam through a massive steam network to every building on campus. Each building then used the steam to generate hot water for domestic hot water usage and space heating. Unlike the steam system, the site’s chilled water production occurred in seven different chiller plants spread across the campus, which fed four separate chilled water loops. Finding a solution required careful planning.

The hospital’s leadership wanted the CHP solution to power as much of the hospital’s electrical loads as possible, while also supplying steam and chilled water to maximize the overall CHP system efficiency. With these priorities in mind, Unison Energy analyzed the breakdown of electrical usage for all 12 meters on site and found that three of the meters made up the lion’s share of power consumption. Two of these large meters were located in the same electrical room in the hospital’s West Tower, while the third and largest meter was over 1,000 feet away in the North Tower.

To maximize on-site electrical generation for the hospital, Unison Energy decided on a two-engine CHP solution that included one 1,506 kW generator to power the single meter at the site’s North Tower at 4.16 kV, and one 1,506 kW generator to power the West Tower’s two meters at 12.5 kV. Unison specified new electrical switchgear to enable the Genset to power both of the West Tower’s meters with a single electrical feed. As a whole, this system was designed to have a total gross generating capacity of 3,012 kW and built to cover the hospital’s entire base load as well as 89% of its annual peak demand.

When determining the location for the CHP engines, Unison Energy had to reckon with space constraints on the dense campus and the need to provide thermal benefits for the facilities. The selected location for both CHP engines was a tight 60 x 75-foot space adjacent to an active loading dock. This location was chosen in part because it was only 150 feet from the hospital’s central boiler plant, which allowed for easy connection to the central steam system and enabled the CHP’s heat recovery steam generator to send 4,500 pounds of steam per hour at 60 PSIG. This location required long electrical runs of 1,200 and 1,600 feet respectively to the North and West Towers — and although these long electrical runs increased the cost of the project, this solution was significantly cheaper than running long mechanical pipes for steam or water and ultimately proved the most feasible from both a technical and economic perspective.

Today, the microgrid is designed to offset 92% of the hospital’s annual electricity usage from the local utility and supply the campus with both heat and chilled water. The hospital’s CHP system is configured to supply chilled water to one of the campus chiller plants via a 343-ton absorption chiller within the CHP yard and a 400-foot chilled water pipe. Additionally, the microgrid project allows for the replacement of the steam plant’s old existing boilers with modern Cleaver Brooks fire tube boilers. The new combined boiler plant and CHP system are designed to have a capacity of 24,700 lb steam/hr or nearly double the hospital’s peak steam demand.

As a whole, the CHP system is engineered to operate at a greater than 78% efficiency on an HHV basis, compared to an average of 40-45% for utility power plants. This allows the hospital to reduce the campus’s carbon footprint by 15% versus the California grid and is designed to save over 15% on utility bills. At the same time, both generators are equipped with island mode capabilities to add resilient power to the hospital’s loads should a prolonged utility outage occur.

Multi-Building Microgrids Offer Critical Benefits

Campuses with multiple buildings and limited space at the central plant can still enjoy the benefits of microgrids, including cost savings, emissions reductions, and resiliency.

Microgrids offer critical benefits to large campuses, including significant savings on utility bills, emissions reductions that help facilities meet sustainability targets, and improved resiliency when power outages occur.

Campuses that have been built out over years present unique challenges, such as multiple electrical feeds, a central utility plant with thermal loops around campus, or distributed boiler rooms and chiller plants located around the campus. Distributed generation can be installed centrally or split into smaller systems located around the campus to address the largest and most critical loads.

Unison Energy works with our clients to identify solutions for complex operating environments. We design, build, own, and operate microgrid solutions using a long-term energy services agreement for campus environments.

If you are interested in the cost-saving, resiliency, and sustainability benefits of a microgrid for your multi-building campus, click here to contact a Unison Energy sales representative.

Energy insights, delivered

Subscribe for more content.