Service Operations – The Principles of Excellence in Practice at Unison Energy

The Unison Energy operations model follows five core principles that support client success and ensure industry-leading uptime.

Unison Energy is changing the game in service operations. Rather than focusing on issue-by-issue resolution, we offer clients an integrated operations framework focused on achieving and maintaining industry-leading asset availability.

This approach is diametrically opposed to typical service contracts. For many facilities, when an issue arises, the customer must call the repairman, who is paid at an hourly rate for each visit and therefore has little reason to resolve the issue quickly or take measures to prevent future visits.

Unison Energy has flipped the priorities and takes a proactive approach to service operations. We focus on uptime for clients, not billable technician hours. In fact, we only get paid when the client’s system is operating. To ensure both industry-leading uptime and long-term client success, we use the following five principles for service operations excellence:

1. Monitor Actively and Clear Faults Remotely

The Unison Energy operations model includes a fully staffed, 24/7 remote monitoring center to track system data and flag any issues that arise. Sensors capture 600-800 data points per site in real time, fully monitoring not only the generators but the entire system, including pumps, thermal flows, site usage, facility interfaces, and utility performance.

Our philosophy is to aggressively monitor as much data as possible on the performance of the entire system in order to detect issues before they occur. If an error occurs, our remote monitoring team can investigate the site’s metrics and, in most cases, reset the systems remotely to resolve the problem. Or they can easily notify the site’s designated technician to enable a fast, in-person response.

Unison Energy technicians receive relevant alerts from the remote monitoring team the moment an error or system fault is detected. They can then make decisions remotely, if appropriate — which helps sites get back online in minutes, rather than the hours it would take for an in-person visit. While Unison techs are responsible for their sites on a 24/7 basis, the remote monitoring team allows them to focus on taking action, rather than constantly monitoring site data (which might actually cause them to miss issues).

This improves both asset uptime and technician lifestyle. In the first six months of 2020, our remote monitoring team cleared just over 90% of faults remotely, allowing our technicians to focus on the issues that needed to be dealt with on-site.

2. Invest in Advanced Data Analytics to Identify and Prevent Issues Before They Occur

The best way to work more effectively is by having less work to do. Investing in advanced data analytics allows Unison Energy to predict outages before they occur, replace worn parts ahead of schedule, and identify common themes for the continuous improvement program. As a result, fewer events occur, outage times are shorter, and the team can focus more on proactive maintenance than reactive problem-solving.

We believe in the importance of capturing and retaining a data archive because it is difficult, if not impossible, to anticipate when historical data will become useful or relevant. Most energy companies only monitor generator performance and only in real-time — without retaining that data for future reference or monitoring performance metrics for the rest of the site. Unison Energy both collects and analyzes 50-80 million data points at each site every day and retains a data warehouse for our predictive analytics algorithms or engineering analysis.

While most engine manufacturers set fault conditions, they are typically related to certain setpoints. We are focused on first identifying leading indicators of faults before they occur, and then analyzing trends, metric comparisons, and outliers that may occur over hours, days, or even months. We have created a library of algorithms built on advanced analytics that are always actively monitoring the data warehouse to identify potential faults.

Technicians and engineers can then use both proprietary monitoring devices and the data warehouse archive to quickly find information with a high level of specificity, for a more successful performance monitoring and review process.

3. Use Tools to Drive Data Sharing and Collaboration to Resolve Remotely

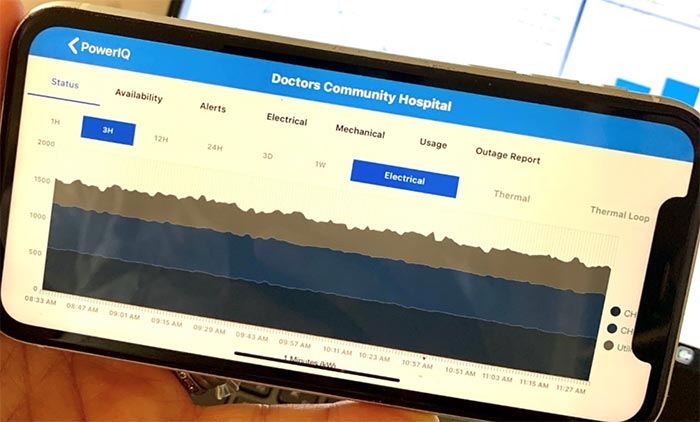

Unison Energy uses tools designed for fast, transparent teamwork and coordination. We have built a proprietary remote monitoring system to allow team members to examine specific data points from customer sites or to track current performance and trends.

This app is available to Unison Energy technicians, remote monitoring team, engineers, analysts, sales representatives, and clients. Whether the team is monitoring real-time normal operations or collaborating on an issue by analyzing historical data, everyone in the organization is able to quickly access and assess the status of current issues.

Alongside this data-sharing tool, Unison Energy uses a proprietary instant messaging application built to enable instant company-wide communication. The application is set up so that each customer site has a dedicated channel where technicians, monitoring center operators, sales representatives, engineers, and executives participate in the conversation.

These channels allow technicians and operators to coordinate responses and share photos or videos of problems or resolutions, allowing the entire team to learn from incidents at individual sites.

4. Create a Culture of Continuous Improvement

Many organizations talk about “lessons learned,” but in reality, it is rare for companies to take a systematic approach to use site failures and errors as learning opportunities.

Every month, Unison Energy’s lead service technicians, engineers, and executives meet to review every fault and outage from the last month across the entire fleet. They look for trends and recurring issues and brainstorm ideas for how to prevent or shorten the duration of future outages. They examine inventory levels, standard operating procedures, issues with parts, and supplier or contractor responses. Thanks to hundreds of data points per site, Unison can use in-depth data analytics to support these monthly reviews and highlight potential problems.

Frequently, Unison Energy identifies an issue at a site and figures out how we could have prevented that issue. With historical data, we can ask ourselves, “Where else were these conditions present, and what could we have observed leading up to the event?” With more data samples, we can more easily identify root causes. This enables our team to make changes across the fleet, pushing preventative actions into standard operating procedures, incorporating data signals into alert algorithms, and automatically generating preventative or reactive work orders to make sure that not only are the lessons learned but that the solutions are systematically incorporated in daily operations.

By looking at all of this information on a regular basis, Unison Energy can identify specific areas for improvement — and monitor performance to confirm those changes have been successful over time.

5. Put Technicians at the Center

Technicians are at the center of everything Unison Energy does. They own the sites, are responsible for the uptime of the site, and serve as the front line of client relationships. Our technicians are responsible for developing in-house training programs and a safety culture.

Every energy company must hire experienced technicians and invest in their training. Unison Energy takes it a step further and empowers our service team by assigning each technician ownership of a site. Each technician is then responsible for the operation of that site, including preventive maintenance, site cleanup, safety equipment, monitoring, and first response. This ownership means Unison technicians are intimately familiar with what it takes to keep their individual sites operating optimally.

Technicians are authorized to take action immediately at the site. They have an expense limit that does not require prior approval, which means they can order parts, run to the nearest electrical parts store, or just purchase supplies because they are best positioned to know what will keep the site at optimal operational efficiency.

Because Unison Energy technicians are responsible for sites and not billable hours, they are salaried and receive quarterly cash bonuses based on uptime, which rewards the team for preventive maintenance and response time — which is also aligned with our clients’ needs. This is in direct contrast to the ineffective break/fix model, where repairmen are paid only when an issue occurs and managers are judged by technician billable hours.

The Unison Energy Culture of Success

Ultimately, Unison Energy believes that creating the right company culture is the necessary foundation for success. The proof is in the results. Unison maintains an average uptime of 97-98% across all sites. While most organizations will cite certain industry metrics that report 92-95% uptime, the truth is that many competitors cannot support those claims with hard data because they do not have the data collection systems in place to accurately measure their performance metrics.

At Unison Energy, we succeed because the focus is on what matters most: ensuring high system uptime so our clients continue to enjoy the sustainability, resiliency, and cost-saving benefits that our microgrids are designed to offer. And because our partnerships are set for 15 to 20 years, that success is not just for today. We have built the model necessary to ensure operational success for years to come.

The Unison Energy service operations model is designed to ensure your facility enjoys all the benefits of a cogeneration-based microgrid. Click here to contact a Unison Energy sales representative.

Energy insights, delivered

Subscribe for more content.