The Path to Decarbonization for U.S. Industrial and Manufacturing Plants

The industrial and manufacturing sector has struggled to reduce emissions due to fuel use and high-heat processes. Today, emerging technologies offer a promising path to carbon neutral.

The industrial and manufacturing sector is increasingly under the spotlight due to its high carbon footprint. Decarbonizing these sites is critical both for corporate ESG goals and on a societal level, but the sector presents a unique challenge due to its technological requirements.

Industrial Emissions Are an Urgent Priority

Globally, the industrial sector accounts for nearly a quarter of CO2 emissions, while the U.S. industrial sector accounted for one-third of all domestic greenhouse gas emissions in 2021. This figure highlights the need — and opportunity — to rapidly lower emissions.

The chemical, iron and steel, cement, and petroleum industries are among the top contributors to this high-emissions picture. Similarly, the food & beverage sector is one of the largest emitters in the U.S, while in 2022 the pulp & paper sector was responsible for almost 2% of all industry emissions.

Industrial Requirements Make Decarbonization Difficult

Industrial processes often require the direct combustion of fuels, and it’s challenging to find alternatives that provide the same level of heat and pressure. Manufacturing cement, glass, steel, fertilizer, and paper requires temperatures ranging from 300 to 1,800 degrees Celsius. About 40% of industrial emissions are from industrial heat production.

Even in states like California, renowned for its environmental consciousness, the industrial sector remains a tough nut to crack. State mandates and bans on natural gas tend to carve out exemptions for the industrial sector, as it’s difficult to avoid fuel combustion in refineries, oil and gas extraction, cement plants, and other major manufacturing industries such as food and beverage, electronics, and aerospace. As of 2020, 23% of the state’s emissions were from industrial sources.

Today’s Technologies Point the Way Forward

Existing and emerging technological solutions provide a promising path to carbon neutral. The U.S. Department of Energy’s Industrial Decarbonization Roadmap outlines key pathways for reducing industrial emissions. Besides electrification whenever possible, the best solutions include energy efficiency, low-carbon fuels, feedstocks, and energy sources (LCFFES), as well as carbon capture and sequestration (CCS).

Energy efficiency

Strategic energy management is required to optimize the on-site use of heat and power. This can include optimizing industrial processes, as through advanced data analytics. The DOE also includes combined heat and power (CHP) as part of this pathway. By using natural gas to support both electric and thermal processes, CHP can cut emissions by 20-60% compared to the utility, while increasing energy efficiency between 65-80%.

Low-carbon fuels, feedstocks, and energy sources

These solutions are pivotal in decarbonizing high-thermal-energy processes. Many sectors will continue to rely on fuel, currently natural gas, due to the cost implications of switching, technological feasibility, or resiliency requirements. Industrial facilities, which require fuel for high-heat processes and thermal loads, contribute up to 30% of their emissions from gas boilers.

- Hydrogen is one alternative, considered a “clean fuel” due to its lack of carbon emissions during combustion. However, hydrogen production may result in emissions, adding to its overall environmental footprint. That being said, zero-carbon methods for hydrogen production exist and will likely become more widespread thanks to incentives in the Inflation Reduction Act.

- Renewable natural gas (RNG) or biogas is another viable alternative and is currently a clean fuel option for some sectors, although the cost is higher than natural gas. RNG can be used as vehicle fuel, for electricity generation, or as a fuel for thermal applications. Once cleaned to an appropriate level it can be directly injected into the pipeline, reducing the carbon intensity of pipeline gas.

Carbon capture and sequestration

Also known as carbon capture, utilization, and storage (CCUS), this is a promising option for industrial sites to reach carbon neutrality. A manufacturing facility can incorporate CCS post-combustion to capture carbon oxides before they are released into the atmosphere. The carbon can then be stored in geological formations or repurposed for commercial or chemical processes. Separating carbon oxides from emission streams and transporting them to storage sites or other applications can be complex and costly, requiring substantial infrastructure, such as pipelines. However, the Inflation Reduction Act provides financial incentives that enhance the economic viability of CCS projects, spurring rapid development in this area.

Industrial Sites Can Make a Difference with CHP

A combined heat and power microgrid can incorporate the best of the DOE’s strategy, as it improves power and thermal efficiency, can utilize low-carbon fuels as they become available, and can integrate with CCS post-combustion for carbon neutrality.

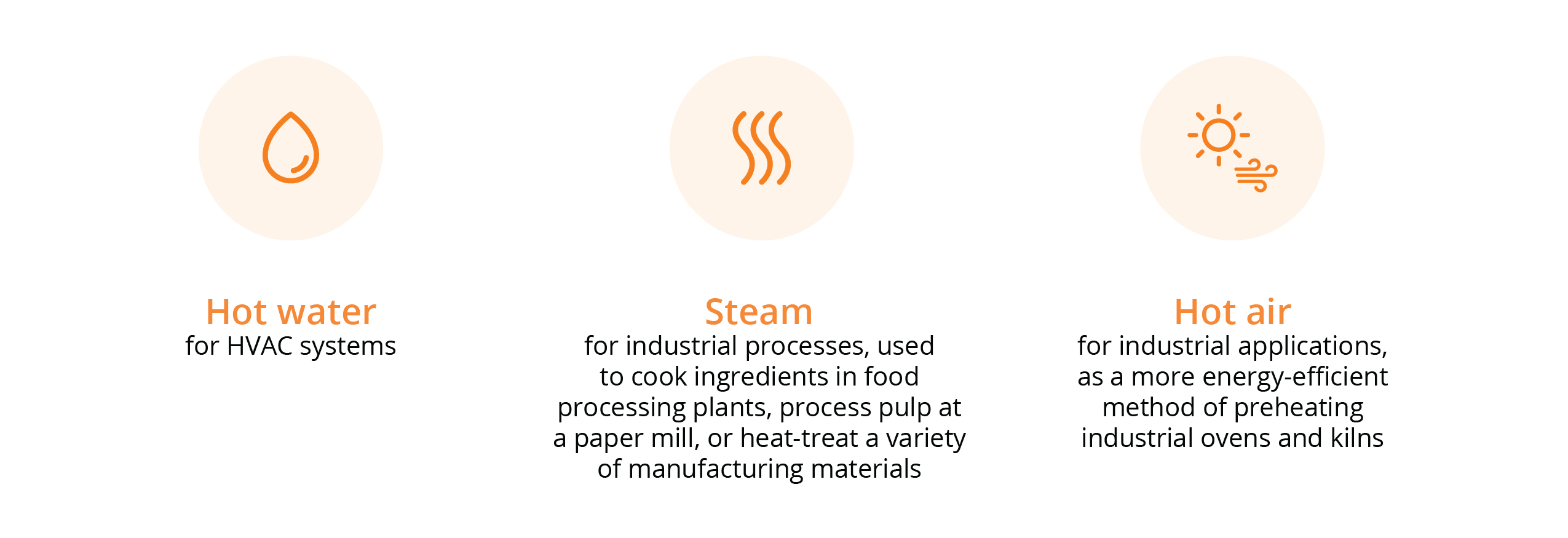

CHP offers heat recovery, integrating with hot water, steam, or chilled water systems to help support a range of specific facility thermal usages, including the following:

CHP can utilize low-carbon fuels like hydrogen and RNG as they become financially viable. Hydrogen or RNG can be mixed with natural gas in pipelines to lower emissions for end users.

CHP can integrate with CCS, enabling a facility to reach net-zero emissions by capturing post-combustion emissions from the CHP system as well as carbon from boilers and other flue gas sources.

Work with Unison Energy for a Path to Carbon Neutral

Unison Energy’s team is experienced in industrial retrofits and takes your unique needs into account each step of the way. We provide microgrid systems that cut your emissions for a path to carbon neutral, while offering critical operational resiliency and significant savings on your energy bill. With no upfront investment required from your facility, a partner like Unison Energy provides an actionable path forward.

Contact us to learn more about the benefits a Unison Energy microgrid could offer your industrial facility.

Energy insights, delivered

Subscribe for more content.